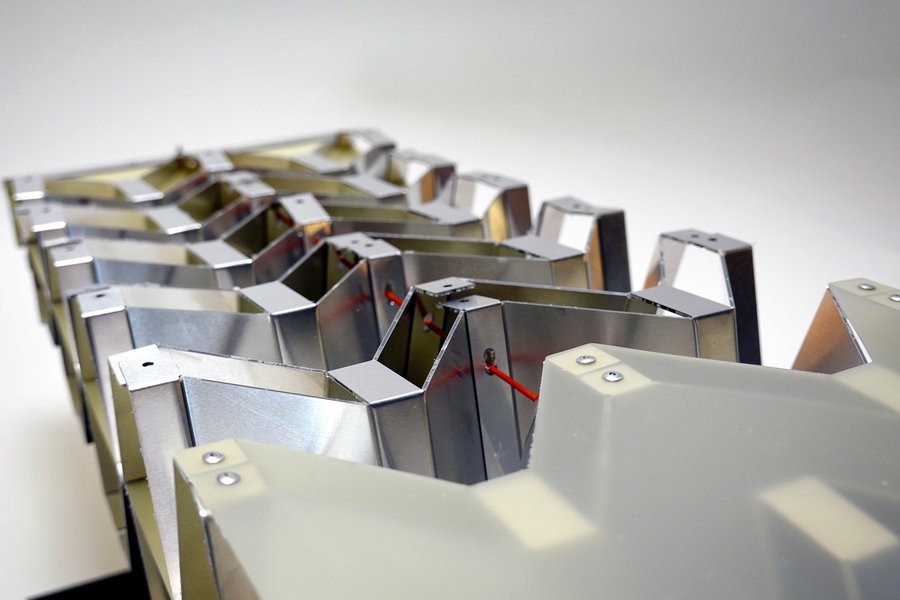

MIT researchers used kirigami, the artwork of Japanese paper slicing and folding, to develop ultrastrong, light-weight supplies which have tunable mechanical properties, like stiffness and suppleness. These supplies might be utilized in airplanes, cars, or spacecraft. Picture: Courtesy of the researchers

By Adam Zewe | MIT Information

Mobile solids are supplies composed of many cells which were packed collectively, reminiscent of a honeycomb. The form of these cells largely determines the fabric’s mechanical properties, together with its stiffness or power. Bones, as an illustration, are crammed with a pure materials that allows them to be light-weight, however stiff and robust.

Impressed by bones and different mobile solids present in nature, people have used the identical idea to develop architected supplies. By altering the geometry of the unit cells that make up these supplies, researchers can customise the fabric’s mechanical, thermal, or acoustic properties. Architected supplies are utilized in many purposes, from shock-absorbing packing foam to heat-regulating radiators.

Utilizing kirigami, the traditional Japanese artwork of folding and slicing paper, MIT researchers have now manufactured a kind of high-performance architected materials often known as a plate lattice, on a a lot bigger scale than scientists have beforehand been capable of obtain by additive fabrication. This system permits them to create these constructions from metallic or different supplies with customized shapes and particularly tailor-made mechanical properties.

“This materials is like metal cork. It’s lighter than cork, however with excessive power and excessive stiffness,” says Professor Neil Gershenfeld, who leads the Middle for Bits and Atoms (CBA) at MIT and is senior creator of a new paper on this strategy.

The researchers developed a modular development course of by which many smaller parts are fashioned, folded, and assembled into 3D shapes. Utilizing this technique, they fabricated ultralight and ultrastrong constructions and robots that, below a specified load, can morph and maintain their form.

As a result of these constructions are light-weight however robust, stiff, and comparatively simple to mass-produce at bigger scales, they might be particularly helpful in architectural, airplane, automotive, or aerospace parts.

Becoming a member of Gershenfeld on the paper are co-lead authors Alfonso Parra Rubio, a analysis assistant within the CBA, and Klara Mundilova, an MIT electrical engineering and laptop science graduate pupil; together with David Preiss, a graduate pupil within the CBA; and Erik D. Demaine, an MIT professor of laptop science. The analysis will probably be introduced at ASME’s Computers and Information in Engineering Conference.

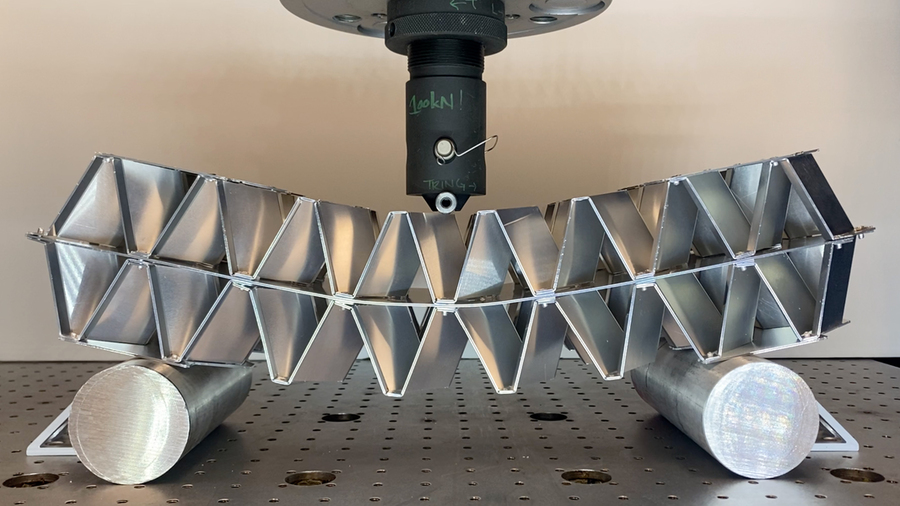

The researchers actuate a corrugated construction by tensioning metal wires throughout the compliant surfaces after which connecting them to a system of pulleys and motors, enabling the construction to bend in both route. Picture: Courtesy of the researchers

Fabricating by folding

Architected supplies, like lattices, are sometimes used as cores for a kind of composite materials often known as a sandwich construction. To examine a sandwich construction, consider an airplane wing, the place a sequence of intersecting, diagonal beams kind a lattice core that’s sandwiched between a prime and backside panel. This truss lattice has excessive stiffness and power, but may be very light-weight.

Plate lattices are mobile constructions produced from three-dimensional intersections of plates, somewhat than beams. These high-performance constructions are even stronger and stiffer than truss lattices, however their advanced form makes them difficult to manufacture utilizing widespread methods like 3D printing, particularly for large-scale engineering purposes.

The MIT researchers overcame these manufacturing challenges utilizing kirigami, a method for making 3D shapes by folding and slicing paper that traces its historical past to Japanese artists within the seventh century.

Kirigami has been used to supply plate lattices from partially folded zigzag creases. However to make a sandwich construction, one should connect flat plates to the highest and backside of this corrugated core onto the slender factors fashioned by the zigzag creases. This typically requires robust adhesives or welding methods that may make meeting gradual, pricey, and difficult to scale.

The MIT researchers modified a typical origami crease sample, often known as a Miura-ori sample, so the sharp factors of the corrugated construction are reworked into sides. The sides, like these on a diamond, present flat surfaces to which the plates will be connected extra simply, with bolts or rivets.

The MIT researchers modified a typical origami crease sample, often known as a Miura-ori sample, so the sharp factors of the corrugated construction are reworked into sides. The sides, like these on a diamond, present flat surfaces to which the plates will be connected extra simply, with bolts or rivets. Picture: Courtesy of the researchers

“Plate lattices outperform beam lattices in power and stiffness whereas sustaining the identical weight and inside construction,” says Parra Rubio. “Reaching the H-S higher sure for theoretical stiffness and power has been demonstrated by nanoscale manufacturing utilizing two-photon lithography. Plate lattices development has been so tough that there was little analysis on the macro scale. We predict folding is a path to simpler utilization of this kind of plate construction produced from metals.”

Customizable properties

Furthermore, the best way the researchers design, fold, and lower the sample permits them to tune sure mechanical properties, reminiscent of stiffness, power, and flexural modulus (the tendency of a cloth to withstand bending). They encode this data, in addition to the 3D form, right into a creasing map that’s used to create these kirigami corrugations.

For example, based mostly on the best way the folds are designed, some cells will be formed in order that they maintain their form when compressed whereas others will be modified in order that they bend. On this method, the researchers can exactly management how totally different areas of the construction will deform when compressed.

As a result of the flexibleness of the construction will be managed, these corrugations might be utilized in robots or different dynamic purposes with elements that transfer, twist, and bend.

To craft bigger constructions like robots, the researchers launched a modular meeting course of. They mass produce smaller crease patterns and assemble them into ultralight and ultrastrong 3D constructions. Smaller constructions have fewer creases, which simplifies the manufacturing course of.

Utilizing the tailored Miura-ori sample, the researchers create a crease sample that can yield their desired form and structural properties. Then they make the most of a singular machine — a Zund slicing desk — to attain a flat, metallic panel that they fold into the 3D form.

“To make issues like automobiles and airplanes, an enormous funding goes into tooling. This manufacturing course of is with out tooling, like 3D printing. However not like 3D printing, our course of can set the restrict for report materials properties,” Gershenfeld says.

Utilizing their technique, they produced aluminum constructions with a compression power of greater than 62 kilonewtons, however a weight of solely 90 kilograms per sq. meter. (Cork weighs about 100 kilograms per sq. meter.) Their constructions have been so robust they might face up to 3 times as a lot pressure as a typical aluminum corrugation.

Utilizing their technique, researchers produced aluminum constructions with a compression power of greater than 62 kilonewtons, however a weight of solely 90 kilograms per sq. meter. Picture: Courtesy of the researchers

The versatile approach might be used for a lot of supplies, reminiscent of metal and composites, making it well-suited for the manufacturing light-weight, shock-absorbing parts for airplanes, cars, or spacecraft.

Nonetheless, the researchers discovered that their technique will be tough to mannequin. So, sooner or later, they plan to develop user-friendly CAD design instruments for these kirigami plate lattice constructions. As well as, they wish to discover strategies to cut back the computational prices of simulating a design that yields desired properties.

“Kirigami corrugations holds thrilling potential for architectural development,” says James Coleman MArch ’14, SM ’14, co-founder of the design for fabrication and set up agency SumPoint, and former vp for innovation and R&D at Zahner, who was not concerned with this work. “In my expertise producing advanced architectural tasks, present strategies for establishing large-scale curved and doubly curved components are materials intensive and wasteful, and thus deemed impractical for many tasks. Whereas the authors’ expertise gives novel options to the aerospace and automotive industries, I consider their cell-based technique may considerably affect the constructed setting. The power to manufacture varied plate lattice geometries with particular properties may allow increased performing and extra expressive buildings with much less materials. Goodbye heavy metal and concrete constructions, hiya light-weight lattices!”

Parra Rubio, Mundilova and different MIT graduate college students additionally used this system to create three large-scale, folded artworks from aluminum composite which are on display at the MIT Media Lab. Although every paintings is a number of meters in size, the constructions solely took just a few hours to manufacture.

“On the finish of the day, the inventive piece is barely potential due to the maths and engineering contributions we’re exhibiting in our papers. However we don’t wish to ignore the aesthetic energy of our work,” Parra Rubio says.

This work was funded, partially, by the Middle for Bits and Atoms Analysis Consortia, an AAUW Worldwide Fellowship, and a GWI Fay Weber Grant.

MIT Information

Source link

#MIT #engineers #kirigami #ultrastrong #light-weight #constructions